20+ years in the field

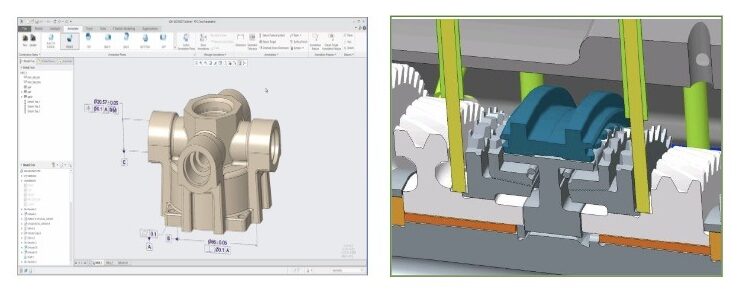

In the field of gearbox development, we primarily deal with the design and testing of mechanical gearboxes and gear shifting.

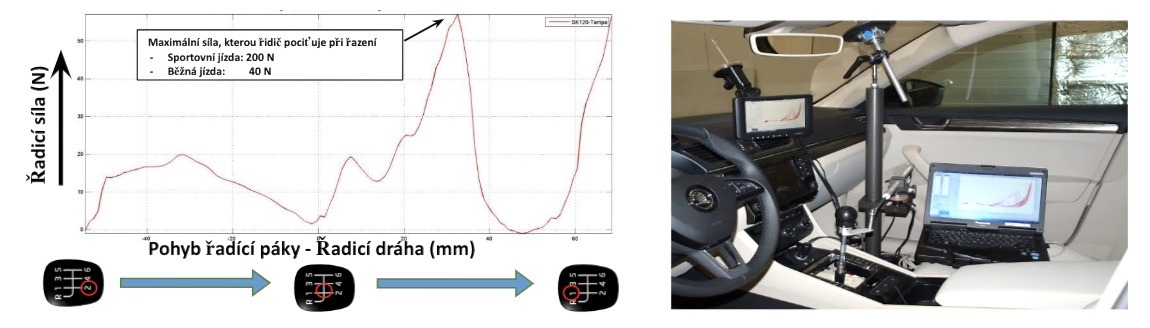

In the field of gearbox development, we primarily deal with the design and testing of mechanical gearboxes and gear shifting. We perform driving tests on a testing track where we use our own measuring equipment. Our technicians are therefore able to evaluate shifting comfort as well as the entire gearbox based on the recored measurements.

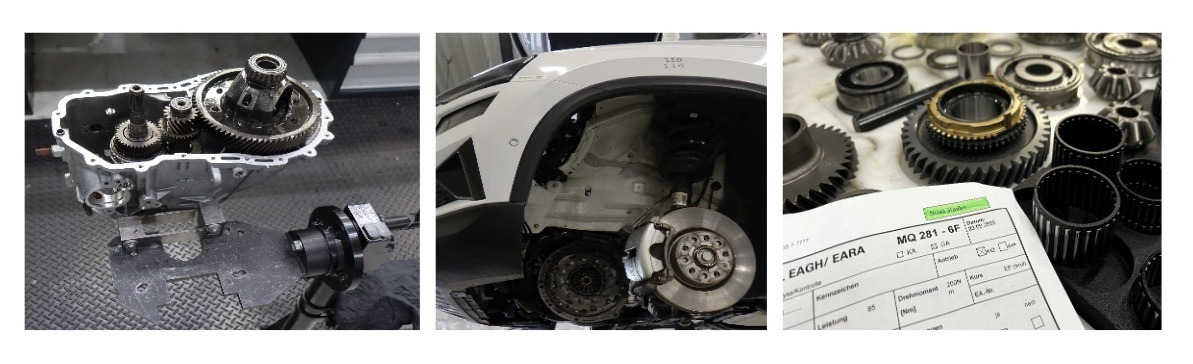

We are also involved in the serialisation of mechanical transmissions for other VW Group subsidiaries worldwide.

Design and implementation of solutions according to the requirements of specific countries, markets and legal regulations of the market in question (e.g. venting in flood areas), while also taking into account changes in related components and related technical systems (clutch, ZMS (dual-mass flywheel), external shifting, etc.)

Implementation of comprehensive model and drawing changes on gearbox parts within the scope of serialisation, model care and further development.

Equipment from PRUSA RESEARCH

Printers help us both in the prototype phase and when drafting designs, as well as when creating various jigs and verification parts, for example, for test benches, workshops, etc. An undeniable advantage of 3D printing is its high speed and low cost.

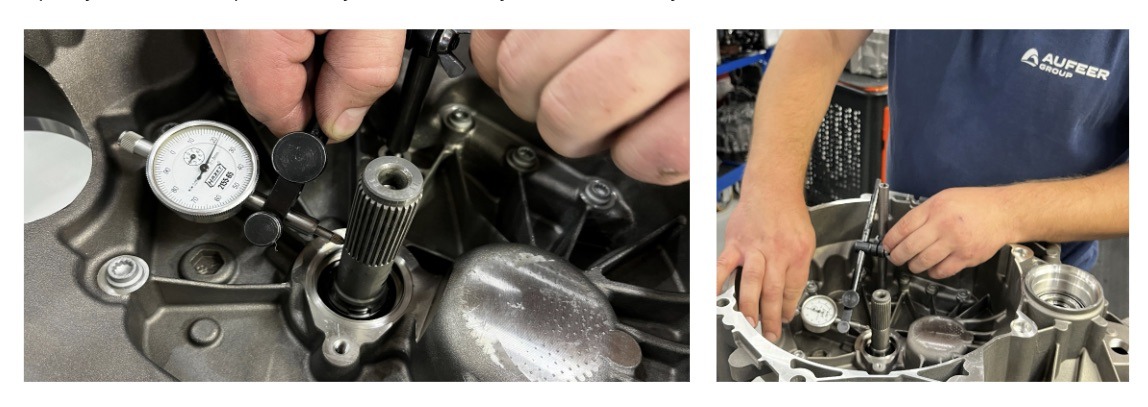

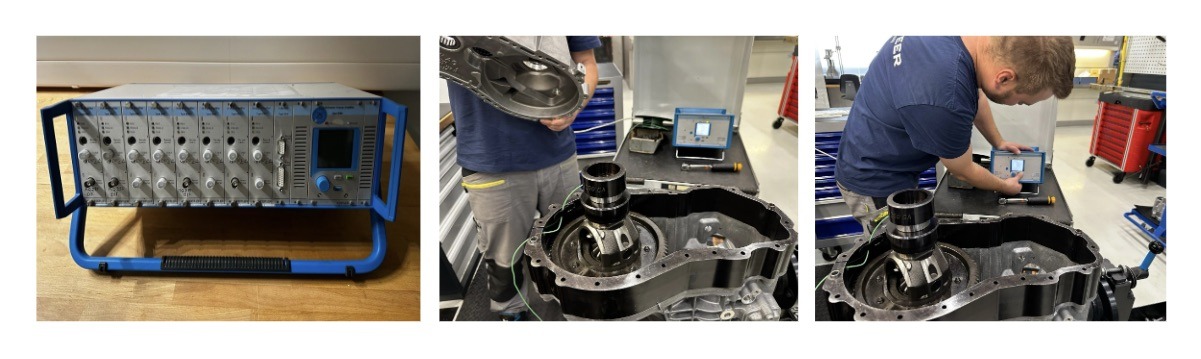

Bearing preload measurement with equipment from the company Kistler

Use of Kistler equipment for determining bearing preload, a computer-controlled press allowing the recording of the course of pressing forces, electronically controlled pressure equipment for measuring leakage, specific fixtures for the assembly and disassembly of gearboxes, etc.

Complete measuring equipment for measuring shaft and differential bearing preload in MQ281, MQ350, MQ500 and DQ200 gearboxes

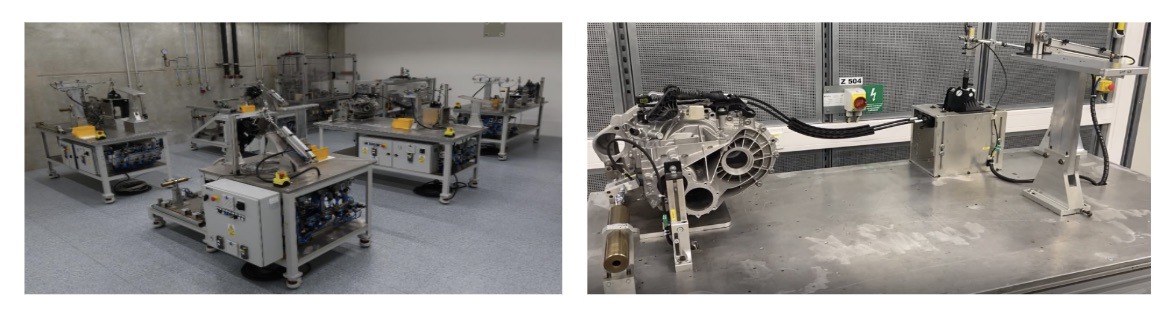

In cooperation with Škoda Auto, we prepare tests of all types of gearboxes, including 4×4 drive, comprising:

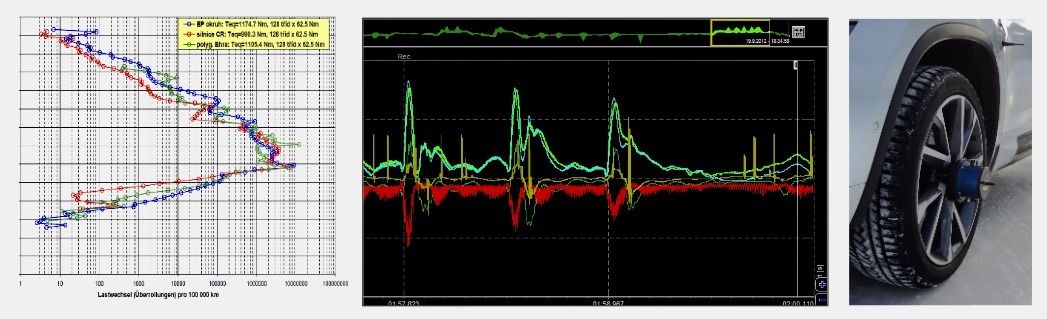

MEASURING STATE

We measure defined shifting characteristics and compare their values with the requirements of the EP 70000 standard or the drawing.

At the end of the equipment’s service life, we then evaluate the change from the initial shifting state.

BLOCK TEST

Gear shifting is blocked against movement, and the gear lever is repeatedly loaded. The shift completes 50,000 cycles in the select direction and another 50,000 cycles in the shift direction.

SPRING ASSEMBLY

In this mode, gear shifting is loaded with 400,000 cycles in the select direction and a total of 1,000,000 cycles in the shift direction in various positions (N-R; 1-2-1; 3-4-3; 5-6-5) at different temperatures.

We provide:

On VW Group vehicles at 100,000 km or according to specifications

We provide technical support for testing on test tracks in Sweden and Finland

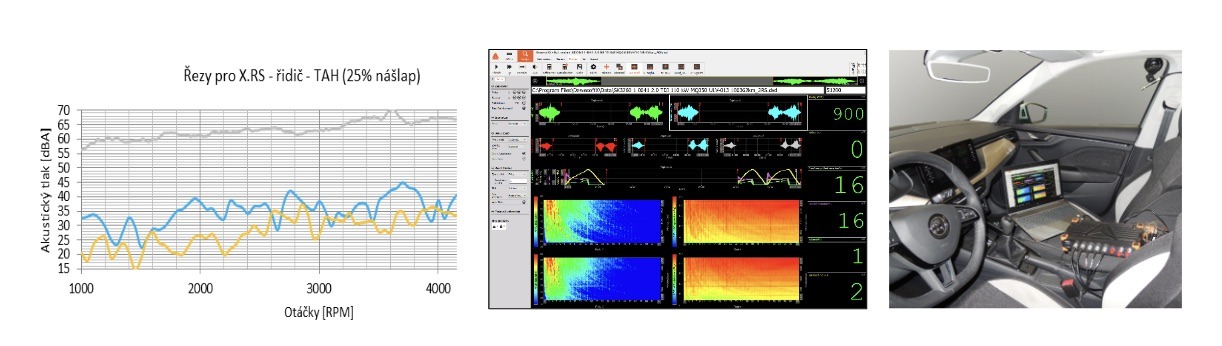

They have knowledge of: Dewesoft Almemo, Catman, Krut, CAN Analyser CANoe, software for G.i.N data loggers.

The measured data is used to calculate the service life of the drive and to simulate PST tests.

We use equipment from the company Dewetron:

Detection of force depending on the path measured on the shift lever

Acoustic spectrum collection of manual gearboxes and 4×4 drives

The results are used as feedback for designers on the effect of modifications on acoustics

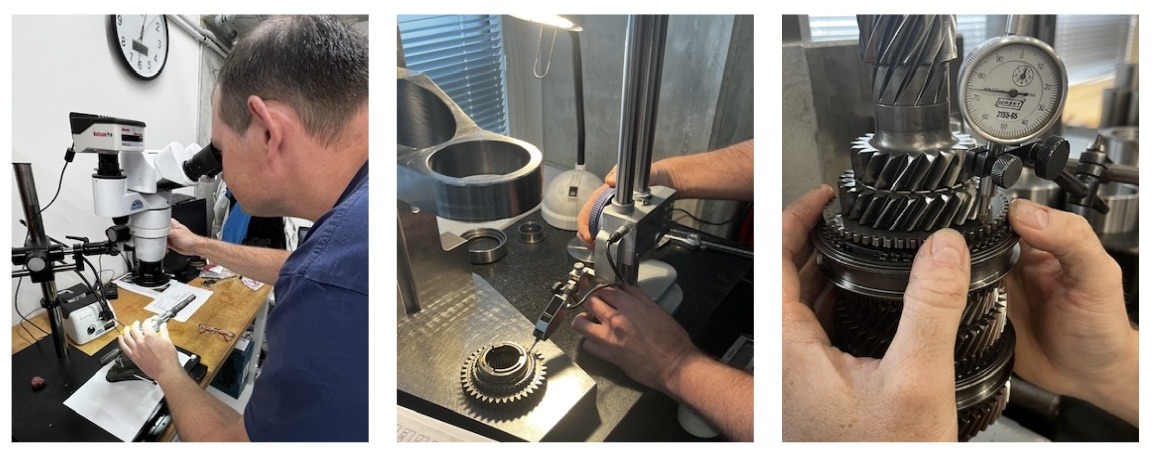

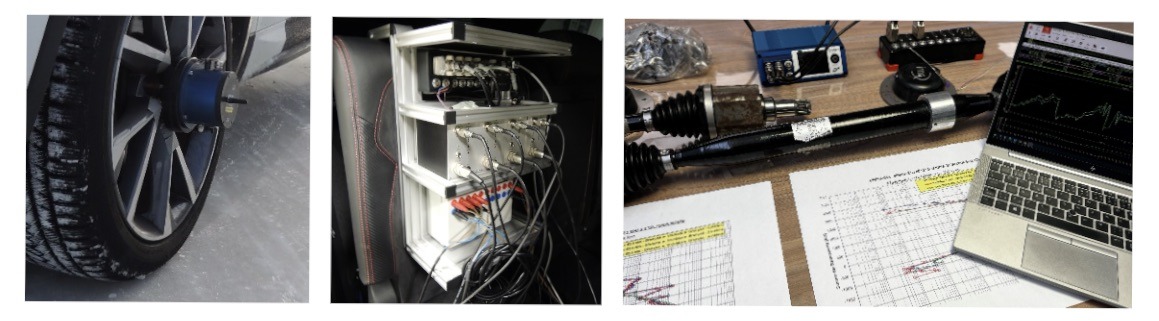

During the analysis, various factors such as wear, damage, defective parts, incorrect assembly or unsuitable material are monitored. Visual inspections, measurement and testing are used to identify the causes of a gearbox breakdown.

The results of the analysis provide important input for adjustments and improvements in gearbox reliability. Based on this information, measures such as material changes, design optimisation, seal modifications or appropriate maintenance can be proposed.

In a laboratory analysis of mechanical gearbox components after a test drive, a detailed evaluation of the condition of individual components is carried out.

Visual wear inspection, synchro height measurement, axial/radial clearance measurement